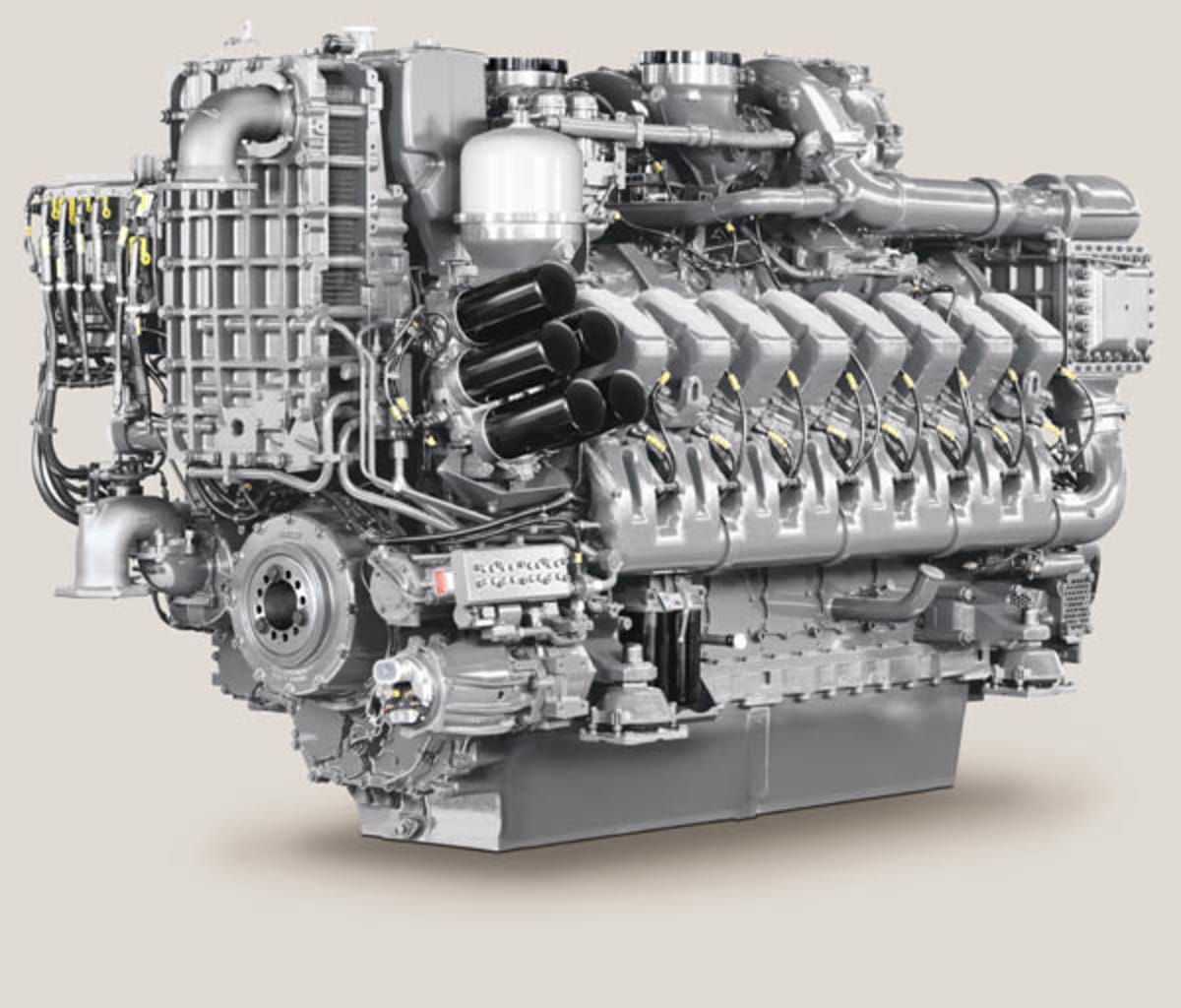

Diesel Engine Test System

In land vehicles, the diesel engine is a power source that stands out with features such as fuel efficiency, high torque, and durability. Diesel engines operate on the principle of compression ignition of diesel fuel and are particularly preferred in applications requiring high power, such as heavy load transportation, construction, and agricultural machinery. The primary function of the engine is to convert the chemical energy of the fuel into mechanical energy, enabling the vehicle to move. Diesel engines offer a more economical driving experience over long distances due to their high thermal efficiency. Additionally, modern diesel engines provide environmentally friendly performance through emission control systems.

Diesel engines undergo various test operations during the production phase and throughout their service life. These tests are conducted to evaluate the engine’s performance, durability, and emission values. Test operations include load tests, emission tests, cooling and lubrication system performance tests, vibration and acoustic tests, and long-term durability tests. These tests analyze how the engine performs under different operating conditions and contribute to improving the design. Furthermore, the engine’s compliance with environmental standards is verified through these tests.

Diesel engine test systems consist of advanced equipment used to measure the engine’s performance and reliability. These systems include components such as dynamometers, emission analyzers, sensors, data acquisition units, and control software. The test systems measure parameters such as torque output, power generation, fuel consumption, emission values, temperature distribution, and vibration levels. In particular, emission tests monitor harmful gas emissions such as NOx (nitrogen oxides), CO (carbon monoxide), and particulate matter. These tests ensure that diesel engines are environmentally friendly and high-performing, while also helping to detect potential failures in advance.

At E2T, we contribute to your development and improvement processes by developing diesel engine test systems tailored to our customers’ needs. Using state-of-the-art systems, our designed diesel engine test systems provide flexibility for different test operations while ensuring high precision in control and measurement capabilities, even during long-term durability tests. This guarantees that your tests are conducted reliably and accurately.

The Advantages We Provide

High Technology and Innovation

By developing innovative solutions under the guidance of advanced technologies, we enhance your test systems to be ready not only for today but also for the future.

Fast Delivery and Installation

We conduct detailed risk analyses to ensure your test system does not require additional time within your project timeline.

Flexibility and Customization

With our flexible and modular designs fully compatible with your test items and test operations, we help you enhance your testing capabilities.

Cost Efficiency

We design your test systems by considering initial investment, energy consumption, spare parts, maintenance, repair, and other sustainability costs, eliminating unnecessary financial burdens.

Quality and Reliability

We design your test systems to be durable under harsh environmental conditions, long-lasting, and low-maintenance, ensuring test results are repeatable, reliable, and fully compliant with international standards.

Advanced Control and Dataacquisition

With our customized, user-friendly E2T Control Suite, we ensure the control and data collection operations of your test systems are performed at high speeds, with precision and security, leaving no room for error.

Training and Documentation

After the installation of your test systems, we provide comprehensive training and documentation to ensure you fully take control of the system.

Maintenance & Repair

We create regular maintenance plans to ensure your test operations run smoothly and respond to unexpected situations within 24 hours.

Human and Environment-Friendly Systems

We develop your test systems with a focus on personnel safety and environmental conditions.