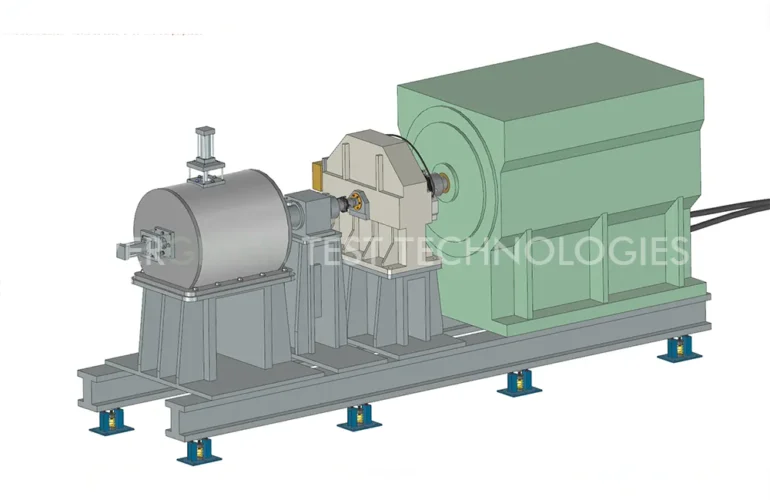

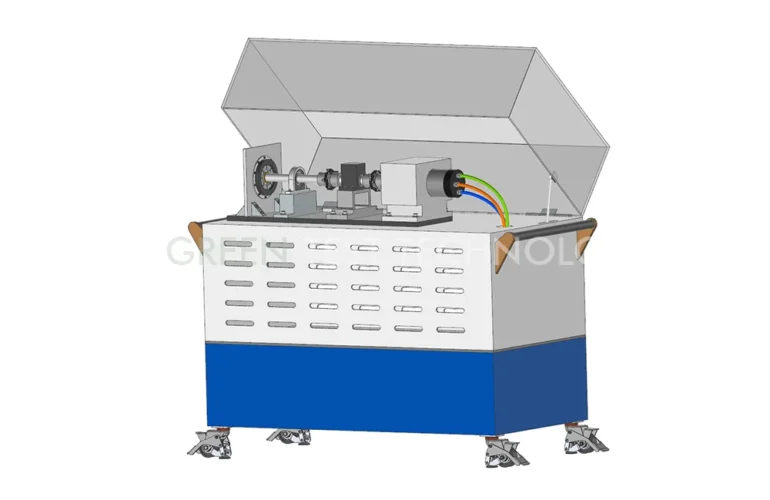

Coating Performance Test Systems

In aircraft engines, various coatings are applied to relevant components to prevent deformations caused by factors such as high and low temperatures, wear, and oxidation-sulfidation. The role of coatings is critically important in aircraft engines with long life requirements; excessive stress-induced deformations not only reduce component performance but can also lead to serious engine damage. Coating performance test systems are used to observe the performance of[…]

Details