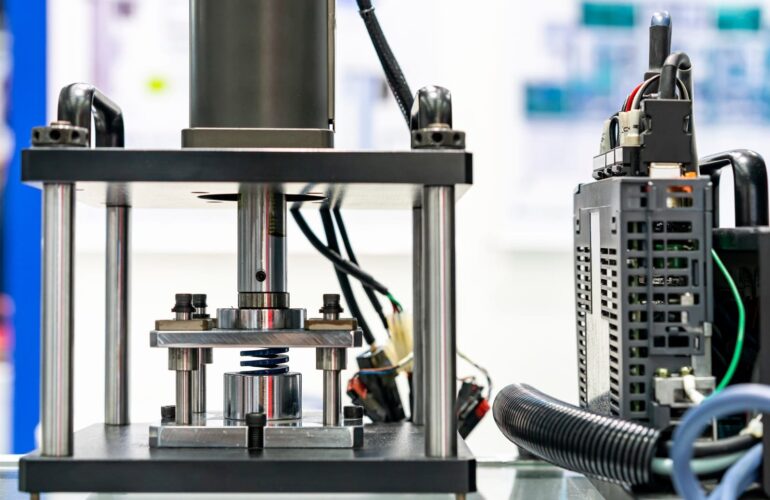

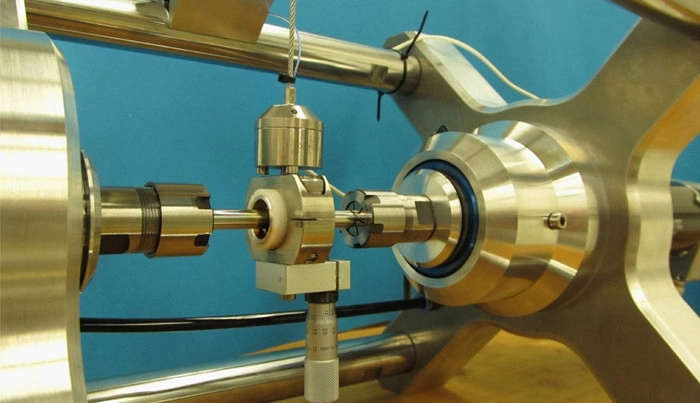

Fatigue Test System

Fatigue test systems are advanced testing platforms designed to evaluate the durability and structural integrity of materials and engineering components under cyclic loading conditions. These systems are essential for identifying the point and mode of failure when components are subjected to prolonged dynamic stresses, thereby enabling accurate estimation of service life through the establishment of the material’s S-N (stress-life) curve. Typically, fatigue test systems utilize hydraulic, electromechanical,[…]

Details