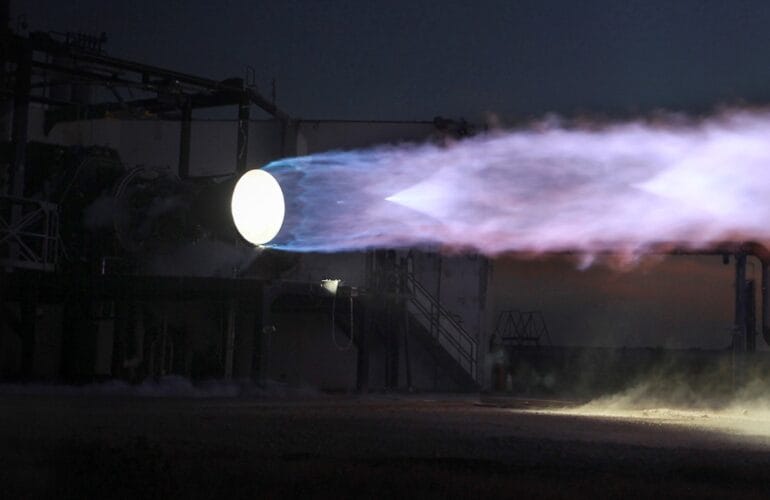

E2T provides specialized test solutions for liquid-fueled rocket engines and other critical systems to its customers in the space sector. In line with our customers' requirements, we develop custom test systems across a wide range, from cold flow tests to strength and lifespan tests. Through turnkey test facility installations, we maximize the reliability, performance, and durability of rocket engines and space systems.

The success of space missions depends on the flawless operation of each component. Therefore, we design and install advanced test systems to measure critical parameters of liquid-fueled rocket engines, such as thrust measurement, combustion efficiency, vibration, and shock resistance. With our developed E2T Control Suite software, we automate your test processes and provide high-precision data acquisition and analysis capabilities. This ensures the repeatability and reliability of your tests.