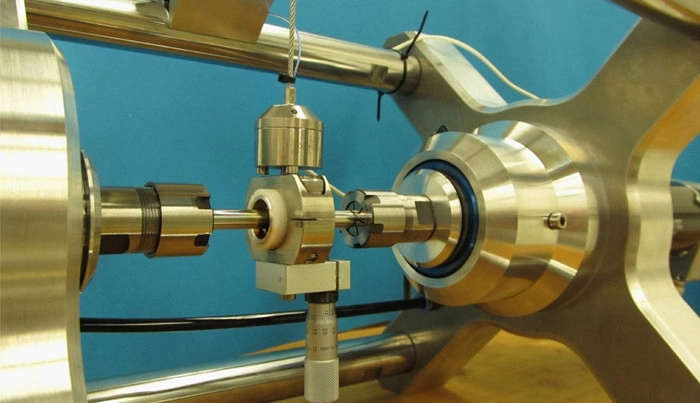

Wear Tear Test System

Wear and tear tests are essential for assessing the durability and service life of moving mechanical, composite, and rubber components that are subject to friction in land vehicles. These tests aim to evaluate the performance of components operating under continuous motion and load, detect potential failures at an early stage, and support material optimization efforts during the development process.

Key parameters measured during testing include wear rate, coefficient of friction, surface degradation, temperature rise, and material loss. The collected data provides valuable insights into the expected lifespan of components and identifies the conditions under which performance degradation reaches critical thresholds.

Wear and tear test systems must demonstrate stable and consistent operation throughout extended test cycles. Therefore, long-term system reliability and robust component selection are critical in system design. High-precision calibration, advanced control capabilities, and accurate data acquisition are also essential for reliable test execution. In addition, these systems must withstand thermal loads, vibrations, and repetitive mechanical stresses. Adherence to international testing standards (such as ISO, ASTM, and SAE) is vital to ensure result validity and repeatability. With these capabilities in place, manufacturers can accurately predict component longevity and engineer more resilient vehicle designs.

At E2T, we support your product development processes by designing and delivering customized wear and tear test systems that can simulate environmental conditions based on your specific requirements.

The Advantages We Provide

High Technology and Innovation

By developing innovative solutions under the guidance of advanced technologies, we enhance your test systems to be ready not only for today but also for the future.

Fast Delivery and Installation

We conduct detailed risk analyses to ensure your test system does not require additional time within your project timeline.

Flexibility and Customization

With our flexible and modular designs fully compatible with your test items and test operations, we help you enhance your testing capabilities.

Cost Efficiency

We design your test systems by considering initial investment, energy consumption, spare parts, maintenance, repair, and other sustainability costs, eliminating unnecessary financial burdens.

Quality and Reliability

We design your test systems to be durable under harsh environmental conditions, long-lasting, and low-maintenance, ensuring test results are repeatable, reliable, and fully compliant with international standards.

Advanced Control and Dataacquisition

With our customized, user-friendly E2T Control Suite, we ensure the control and data collection operations of your test systems are performed at high speeds, with precision and security, leaving no room for error.

Training and Documentation

After the installation of your test systems, we provide comprehensive training and documentation to ensure you fully take control of the system.

Maintenance & Repair

We create regular maintenance plans to ensure your test operations run smoothly and respond to unexpected situations within 24 hours.

Human and Environment-Friendly Systems

We develop your test systems with a focus on personnel safety and environmental conditions.