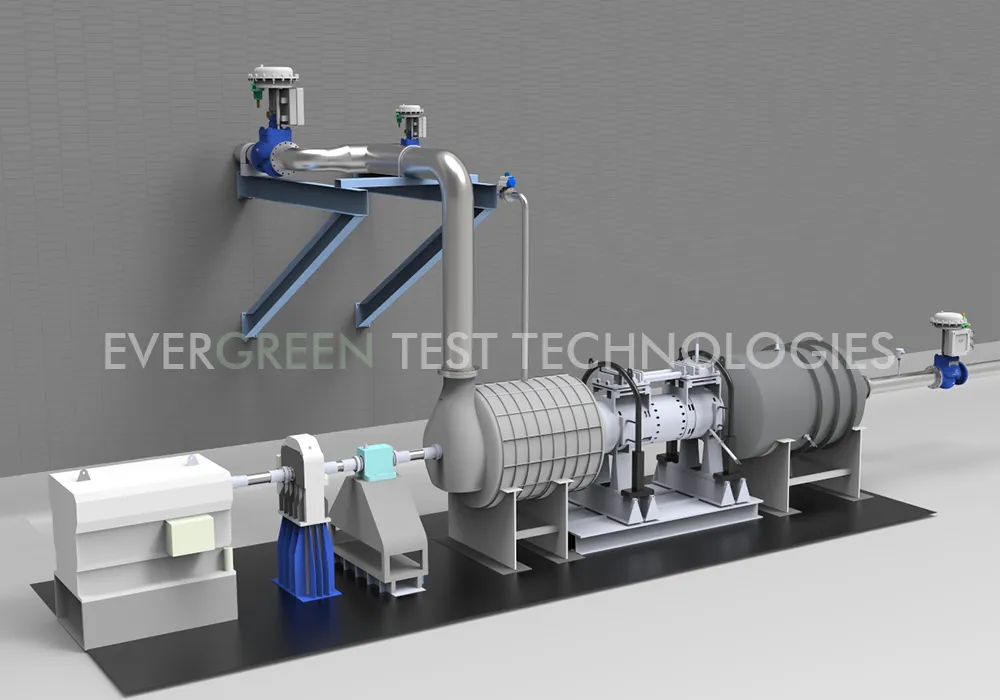

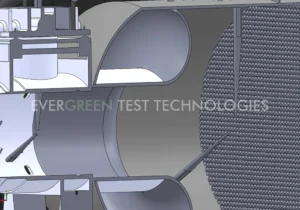

Compressor Test Rig

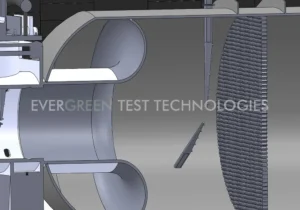

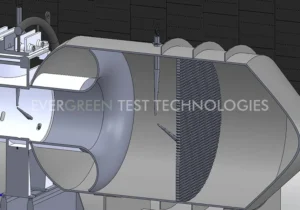

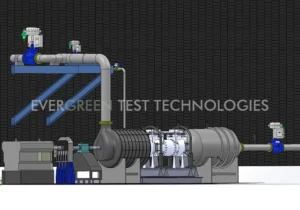

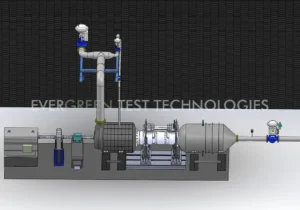

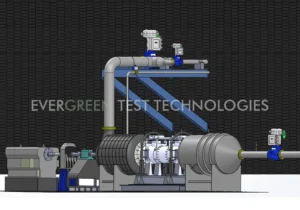

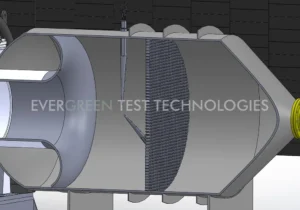

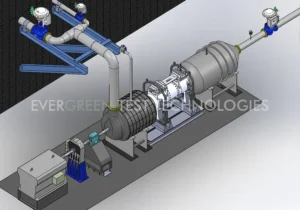

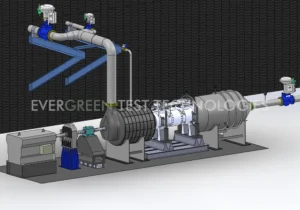

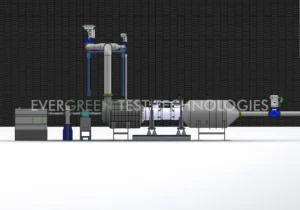

Compressor Test Rigs are complex test systems used to measure the performance of axial, radial, or mixed-flow (axial-radial) compressors in aviation engines, generate compressor maps, and measure Tip Clearances and Blade Tip Timing.

When designing Compressor Test Rigs, they can be resized based on the number of stages, rotational speed, power, and diameter of the compressor to be tested, or they can be designed in full scale according to the infrastructure capacity. In terms of energy consumption, open-loop (blow-down) rigs are generally preferred for small-diameter or down-scaled test articles, while closed-loop (continuous) test rigs are preferred for large-scale, full-size test articles.

The testing processes of compressors, which are among the main components of aviation engines, are highly costly and critical. In addition to customized instrumentation designs and adaptation, precise data acquisition and control capabilities play a significant role in compressor map generation and compressor efficiency measurement tests.

E2T, in line with your Compressor Test Rig needs, not only develops open-loop or closed-loop compressor test rigs but also contributes to your development and testing processes with specialized instrumentation designs, precise data acquisition, and control solutions.

The Advantages We Provide

High Technology and Innovation

By developing innovative solutions under the guidance of advanced technologies, we enhance your test systems to be ready not only for today but also for the future.

Fast Delivery and Installation

We conduct detailed risk analyses to ensure your test system does not require additional time within your project timeline.

Flexibility and Customization

With our flexible and modular designs fully compatible with your test items and test operations, we help you enhance your testing capabilities.

Cost Efficiency

We design your test systems by considering initial investment, energy consumption, spare parts, maintenance, repair, and other sustainability costs, eliminating unnecessary financial burdens.

Quality and Reliability

We design your test systems to be durable under harsh environmental conditions, long-lasting, and low-maintenance, ensuring test results are repeatable, reliable, and fully compliant with international standards.

Advanced Control and Dataacquisition

With our customized, user-friendly E2T Control Suite, we ensure the control and data collection operations of your test systems are performed at high speeds, with precision and security, leaving no room for error.

Training and Documentation

After the installation of your test systems, we provide comprehensive training and documentation to ensure you fully take control of the system.

Maintenance & Repair

We create regular maintenance plans to ensure your test operations run smoothly and respond to unexpected situations within 24 hours.

Human and Environment-Friendly Systems

We develop your test systems with a focus on personnel safety and environmental conditions.